Our Products

Need Help? We Are Here To Help You

Call Us now

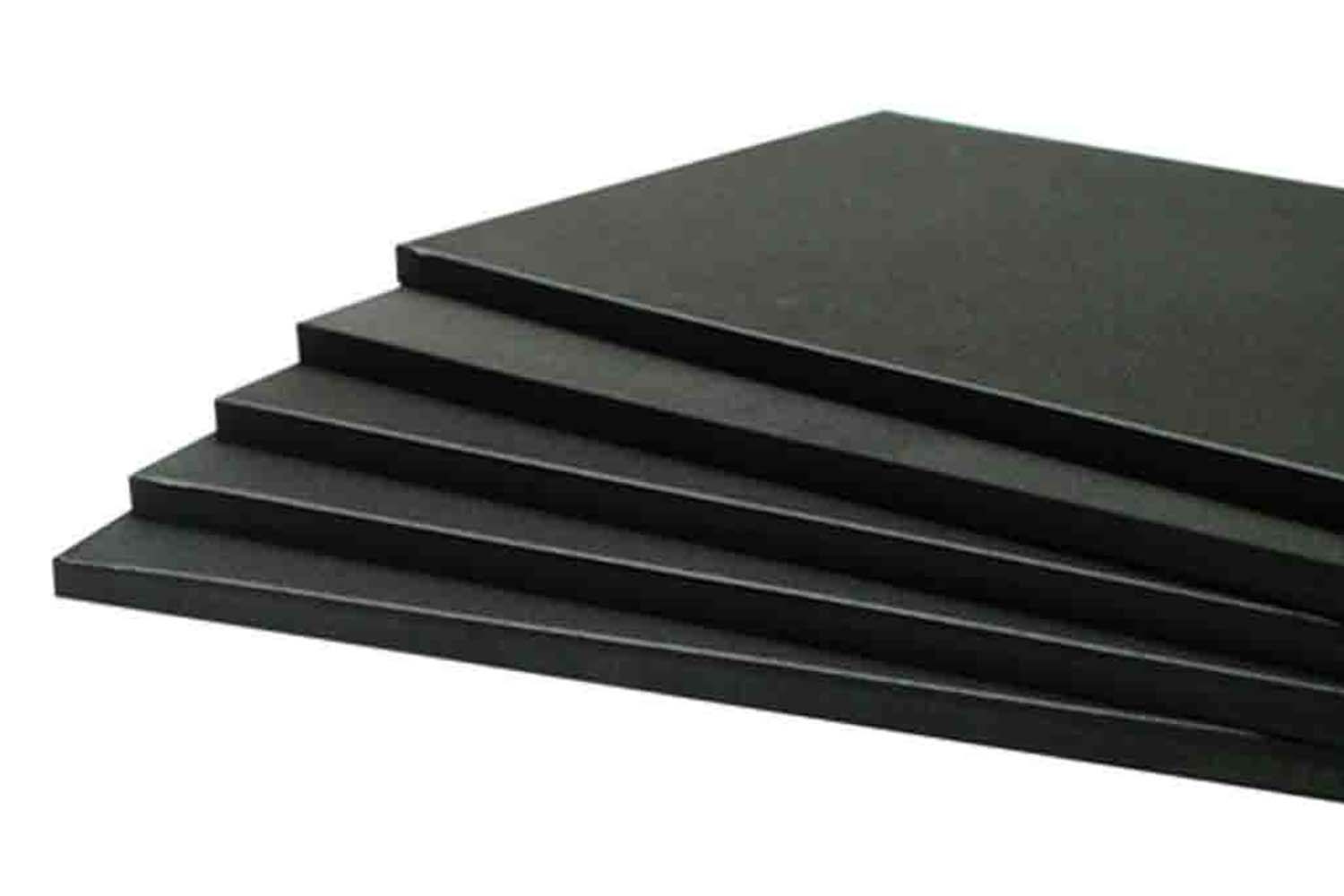

Durable Rubber Foam For Industrial Sealing & Vibration Control

Styrene Butadiene Rubber–based foam is a Reliable, Cost-efficient industrial material designed for applications where abrasion resistance, sealing efficiency, and mechanical durability are critical. At Fusion Foams, We manufacture and supply high-quality rubber foam sheets and rolls engineered for Industrial, automotive, construction, and commercial use.

With advanced production facilities in India, We deliver consistent material performance, dimensional accuracy, and dependable supply for both standard and custom requirements.

What Is Styrene Butadiene Rubber Foam?

This synthetic rubber foam is a closed-cell material known for its balanced mechanical strength, resilience, and wear resistance. It offers dependable cushioning and sealing performance while remaining economical, making it a preferred choice for general-purpose industrial applications.

Unlike softer cushioning materials, this rubber-based solution is engineered for repeated stress, friction, and compression in demanding environments.

Key performance characteristics

This material stands out for its mechanical reliability and long service life:

- High resistance to abrasion and surface wear

- Good tensile strength and tear resistance

- Effective shock absorption and vibration reduction

- Closed-cell structure that limits water, air, and dust penetration

- Reliable performance in general industrial conditions

- Resistance to weak acids, alkalis, and salts

- Better heat-aging properties compared to natural rubber

- Easy cutting, shaping, and fabrication

Typical Technical Overview

Property | Typical Performance |

Density Range | 80–200 kg/m³ |

Cell Structure | Closed-cell |

Operating Temperature | -30°C to +90°C |

Water Resistance | Good |

Oil & Fuel Resistance | Limited |

(For oil-intensive environments, alternative rubber grades may be recommended.)

Applications Across Industries

Thanks to its durability and versatility, this synthetic rubber foam is widely used in applications where wear resistance and mechanical stability are essential:

- Industrial Sealing & Gasketing – gaskets, seals, spacers for water, air, and steam systems

- Automotive Components – vibration pads, anti-squeak parts, cushioning elements

- Construction & Infrastructure – expansion joints, sound insulation, flooring underlays

- Cushioning & Protection – shock-absorbing pads, protective liners, impact buffers

- Appliances & Equipment – vibration isolation and basic sealing

General Industrial Use – conveyor protection, abrasion-resistant liners, machinery padding

Custom Rubber Foam Solutions by Fusion Foams

Different applications require different material characteristics. Fusion Foams provides fully customized solutions based on Styrene Butadiene Rubber to meet specific mechanical and dimensional requirements.

Customization options include:

- Multiple density and hardness grades

- Custom thicknesses and dimensions

- Sheet and roll formats for easy processing

- Precision fabrication including gaskets, seals, pads, and die-cut components

- Optional self-adhesive backing for simplified installation

- Application-specific formulations based on performance needs

Our technical team works closely with customers to ensure optimal material selection and consistent quality.

Why Choose Fusion Foams?

When you partner with Fusion Foams, you benefit from:

- Consistent quality with controlled manufacturing processes

- Cost-effective material solutions for large-scale use

- Technical support for application-based material selection

- Custom fabrication capabilities for complex requirements

- Reliable delivery across India

Looking for Reliable Rubber Foam Sheets or Rolls?

Whether your application requires durable sealing, effective cushioning, or abrasion resistance, Fusion Foams offers engineered solutions built for performance and value. Contact our team to request specifications, samples, or pricing tailored to your requirements.

Frequently Asked Questions (FAQs)

- Is SBR foam water-resistant?

Yes. The closed-cell structure provides good resistance to water, air, and dust, making it suitable for sealing applications. - How does it compare to natural rubber foam?

It generally offers better abrasion resistance, improved heat-aging performance, and a more economical cost profile. - Are adhesive-backed options available?

Yes. Adhesive-backed variants are available to simplify installation and ensure secure placement. - In what formats is it supplied?

It is available in sheets and rolls and can be further fabricated into gaskets, seals, and custom-cut parts. - Is it suitable for oil exposure?

Resistance to oils and fuels is limited. For oil-heavy environments, nitrile-based materials are usually recommended. Get Direction