DISCOVER PREMIUM QUALITY FOAM FOR EVERY NEED !

It Is A Synthetic Rubber, Made From The Saturated Chain Of Polyethylene. Epdm Foam Is A Widely-used Material Across The World And Forms The Foundations For Many Products In Our Day-to-day Lives.

10 +

Years Of Experience

- About Us

Who We Are:

Fusion Foams is a company fueled by a passion for progress and a commitment to delivering exceptional foam solutions. For years, we’ve been a leading manufacturer of high-performance EVA Foam (ethylene vinyl acetate) and cellular Rubber Foam, serving a diverse range of industries. Our strategically located production units in Delhi and Haryana ensure efficient production and reliable deliveries, wherever you are. Our unwavering focus on quality and a relentless pursuit of innovation have made us the trusted partner of businesses and individuals seeking top-tier foam solutions. Offers a vast selection of foams ideal for Applications such as Construction, Automotive, Aerospace, Medical, and Consumer Goods.

- Our Products

Explore Our Products

NEOPRENE FOAM

Neoprene Foam Is A Flexible And Durable Synthetic Rubber Known For Its Excellent Insulation And Water Resistance. Commonly Used In Wetsuits, Medical Braces,mouse Pads And Industrial Gaskets, It Delivers Comfort, Protection.

RUBBER FOAM

Our General Rubber Foam Provides Effective Cushioning, Sealing, And Vibration Isolation. With Various Formulations Available, It Offers A Balanced Combination Of Flexibility And Durability For Diverse Applications In The Automotive.

SILICONE FOAM

Experience Silicone Foam, A High-performance, Closed-cell Foam With Exceptional Resistance To Extreme Temperatures. Perfect For Demanding Applications In The Automotive, Aerospace, And Medical Industries.

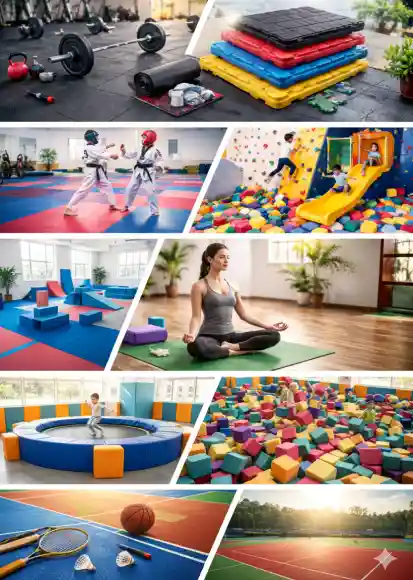

- Applications

Our Applications

Sport & Leisure

Package

House hold

Education & Entertainment

Construction

Acoustics & noise Insulation

Medical Treatment

Automobile Industry

Electrical & Electronic

Marine

- Capabilities

Our Capabilities

- Our Blogs